400-9988-900

400-9988-900

400-9988-900

400-9988-900

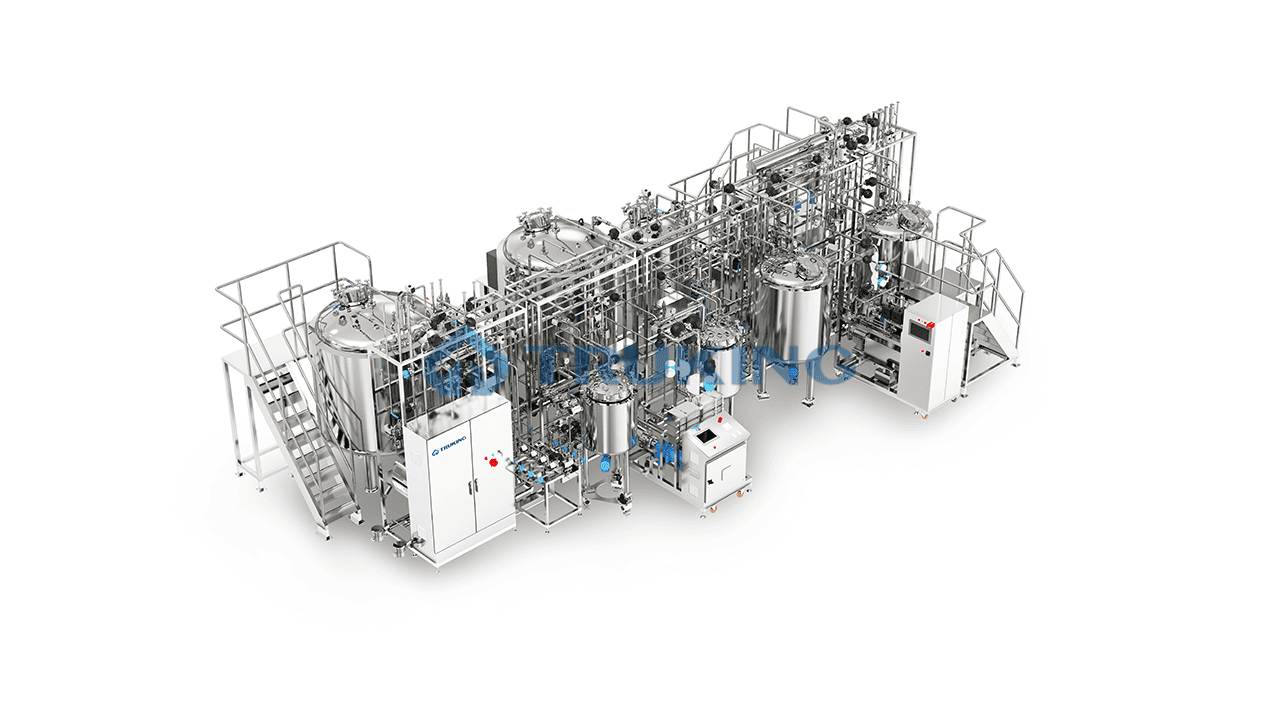

Microspheres

Ø Targeted reaction tank design and model selection of shearing and emulsifying equipment to meet the needs of laboratory scale to production scale.

Ø Non-standard customized aeration device to reduce the residual of organic solvent and to ensure the solidification of microspheres.

Ø Excellent pipeline drop design and filter selection to reduce the residue of liquid medicine.

Ø The design compliments ratio of mixing oil and water to ensure the emulsification effect.

Ø The selection design of the screening machine ensures the uniformity and reproducibility of the evaluation indexes of the particle size distribution of microspheres.

Ø Provide different microsphere preparation methods, adapt todifferent APIs, and ensure the encapsulation rate and drug loading.

Ø The matching isolator system ensures the sterile environment ofthe preparation process.

Liposomes

Ø Reasonable distribution of Mixing tank and emulsifying tank, filter selection and gradient design, to minimize the residual of liquidmedicine.

Ø Non-standard customized aeration device can effectively reduceorganic solvent residues.

Ø Liposome debris collection device to ensure the effective implementation of the back-end process.

Ø Excellent selection and use of shearing equipment and homogeneous emulsification equipment to effectively ensure particle sizedistribution.

Ø The key parameters can be controlled to ensure there producibility of the preparation process.

Fatmilk

Ø The design compliments mixing of oil and water to ensure the emulsification effect.

Ø Inverted tank shearing / homogenizing toensure the complete dispersion and shearing of the liquid medicine. Minor difference of each batch to ensure uniformity and repeatability.

Ø Effective nitrogen protection ensures product quality and safety.

Suspension

Ø Reasonable use of feed isolator and α / βvalve to ensure the sterility and personnel protection of API feeding process.

Ø Reasonable division of auxiliary material preparation tank area, filter selection and gradient design to minimize there sidual of liquid medicine.

Ø The high-speed mixing design of the mixing tank makes sure the uniformity of the drug solution before the ball milling /homogenizing, and ensures the ball milling / homogenization effect.

Ø The special-shaped design of the tank body guarantees the lowest mixing liquid volume.

Ø Circulating ball milling / homogenizing and rear-end filter network design to ensure the uniformity of the finalparticle size distribution.

Ø The circular filling design of the buffer tank avoids the riskof suspension subsidence during the suspension filling process.